Matrelec Premium High Production HF Welder Range

Matrelec's Premium range of welders are designed with a single purpose: maximum productivity with optimum quality. With manual or automated rotary welding stations and linear transfer tables, machines can be configured to suit almost any fabrication work. Matrelec's proprietary WAA Technology automates power adjustment and creates welding profiles which are saved as graphic curves, essential for traceability and reproducibility.

The HF Premium range is perfectly suited for welding, marking and cutting work of PETG, PVC, PU, EVA and PVC or PU coated sheets, fabric and cardboard and all materials with dielectric losses for the design of products such as blister packaging, automotive interior parts, medical, hazmat and safety equipment, sun lounges and inflatable products.

Premium Range Features

- Accelerated production start-up thanks to programmable warm-up.

- Quick series change using a tool indexing system, which enables precise positioning without additional adjustment.

- Welding parameters saved in the form of recipes, allowing a quick series change.

- Manual or automatic cycle operation to optimise production.

- Control panel with Pro-face touchscreen for quick access to settings.

- Many materials can be cut and welded, such as PETG.

- Press bed temperature conditioning for long welds, high speeds or complex materials such as PETG or EVA.

- Automatic detection of the weld recipe depending on the tool installed (optional).

- Consistent weld quality and traceability thanks to WAA Technology.

Q – Linear Transfer Welders

For large format welding, Matrelec's transfer table machines make it possible to produce a wide range of products with low cycle times compared to those of a conventional stationary machine.

With power from 8-15 kW and 500cm2 electrode area, the Q range of welders can efficiently handle a very wide variety of jobs. The welded and four-actuator press structure ensures a perfect distribution of pressure over the entire welding surface and supports high pressure on different formats up to 900 x 1500mm

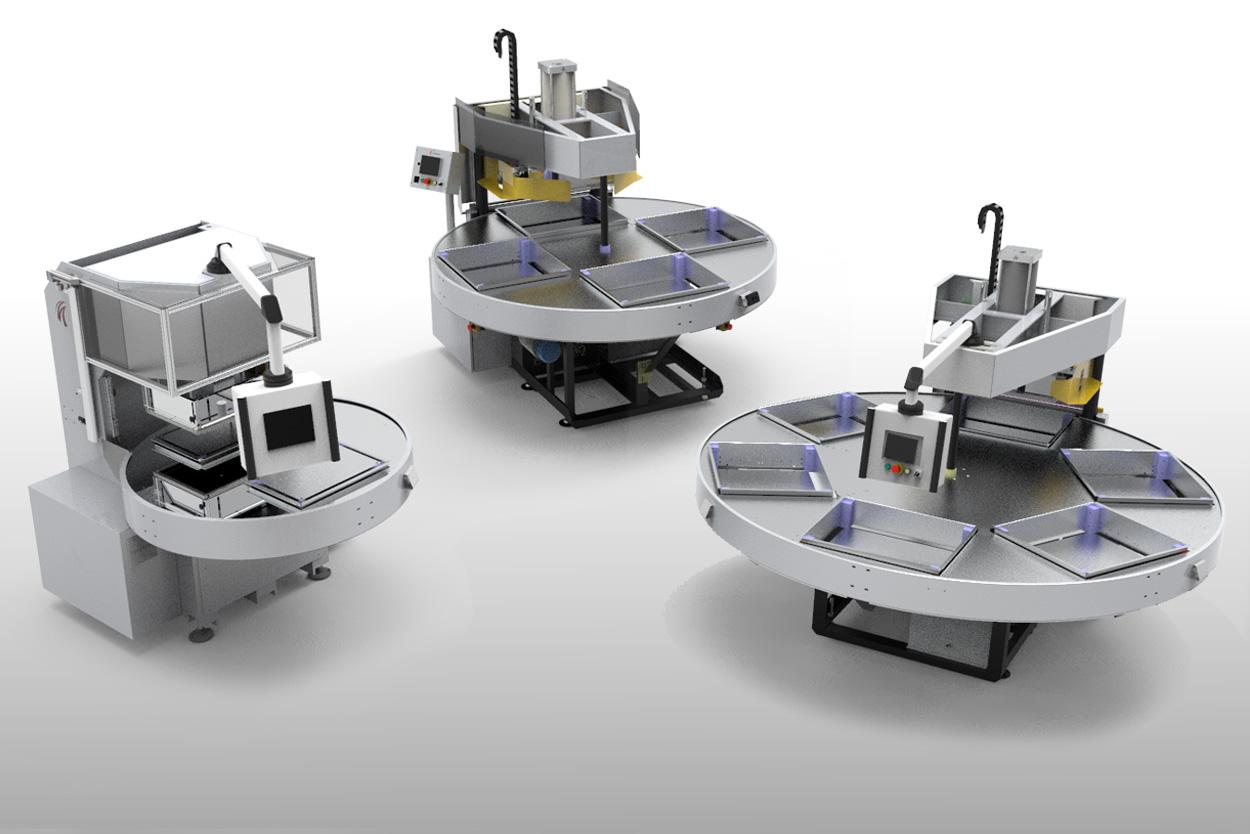

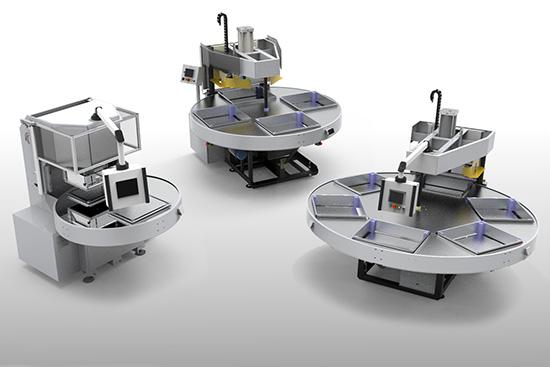

Type T Rotary Tables - 6 to 15 kW

The rotating tables are perfectly suited to high speeds and elaborate fabrication requiring multiple operations.

With up to 6 stations, several operators are able to work on a machine at the same time, alternating product welding and positioning, to minimise cycle time.

For more complex products, each station can be dedicated to a different task and the T series can be optionally equipped with several welding heads.

Contact Aeronaut

Get the facts from the factory direct. If you want advice on automated cutting, an offer on a complete cutting system or to arrange a demonstration, just ask!

Products

Technology

Special Machines

Matrelec HF Welders

Applications

Company

News

Contact Details

Aeronaut Automation

4-6 Tepko Road,

Terrey Hills,

New South Wales 2084

Australia.

Hours: 8:00 - 17:00 Australian Eastern Standard Time

Tel: +612 9450 0800

Sales: Sales@Aeronaut.org

Admin: Admin@Aeronaut.org

Support: Support@Aeronaut.org

Tech: Tech@Aeronaut.org